Canyon Terrace Custom Built Homes are under construction. Even as the Biden administration works to ease the pain at the ports in Long Beach, Los Angeles and elsewhere, contractors are struggling to keep up with the demand for home construction. (Margaret Darby)

Jim Collins, group vice president at the M&T Bank branch in Holladay, was shuffling things around when he answered the phone. Jim was putting boxes in his car, in preparation to move into the home he and his wife, Nancy, are almost done building. “So if I’m out of breath that’s why,” Collins said.

The two have faced similar consequences brought on by the disruption in the global supply chain that many recent homebuilders can relate to. “We still don’t have our refrigerator that we ordered back in November (2020),” Collins said. “We had to buy a different refrigerator to use in the meantime.”

Even as the Biden administration works to ease the pain at the ports in Long Beach, Los Angeles and elsewhere, contractors are struggling to keep up with the demand for home construction. Inventory is lean which makes it difficult for contractors to get the materials they need to build a home. Materials are purchased at much higher costs and received after longer wait times compared to previous years.

The global supply chain does not have the reputation of being a delicate system. “It can take big shocks,” said Scott Webb, a professor of global supply chain management at BYU. Even so, the COVID-19 pandemic’s unpredictable nature sent supply chain risk processes crashing down. Risk management processes were all planned around predictable disasters.

Manufacturers slowed or stopped production during the pandemic to prevent the spread of the virus, but demand for materials kept up according to Webb. The pandemic did more damage to lower income jobs, like factory work, than higher income jobs. People with higher income jobs still wanted new homes but the workers who make new homes possible were not working.

According to the United States Census Bureau, housing starts were up by 13.5% in August 2021 when compared with housing starts in August 2020.

“We did more loans in 2020 than we did in 2019 and we’re on track to do more loans in 2021 than we did in 2020,” Collins said. His company provides capital to builders in the form of loans to fund construction projects.

The slowed rate of production coupled with the spike in demand for new homes uncovered weak links in the supply chain. Factories are now swamped by the surging demand for building materials. As a result, the production times and costs of materials have stretched way beyond normal.

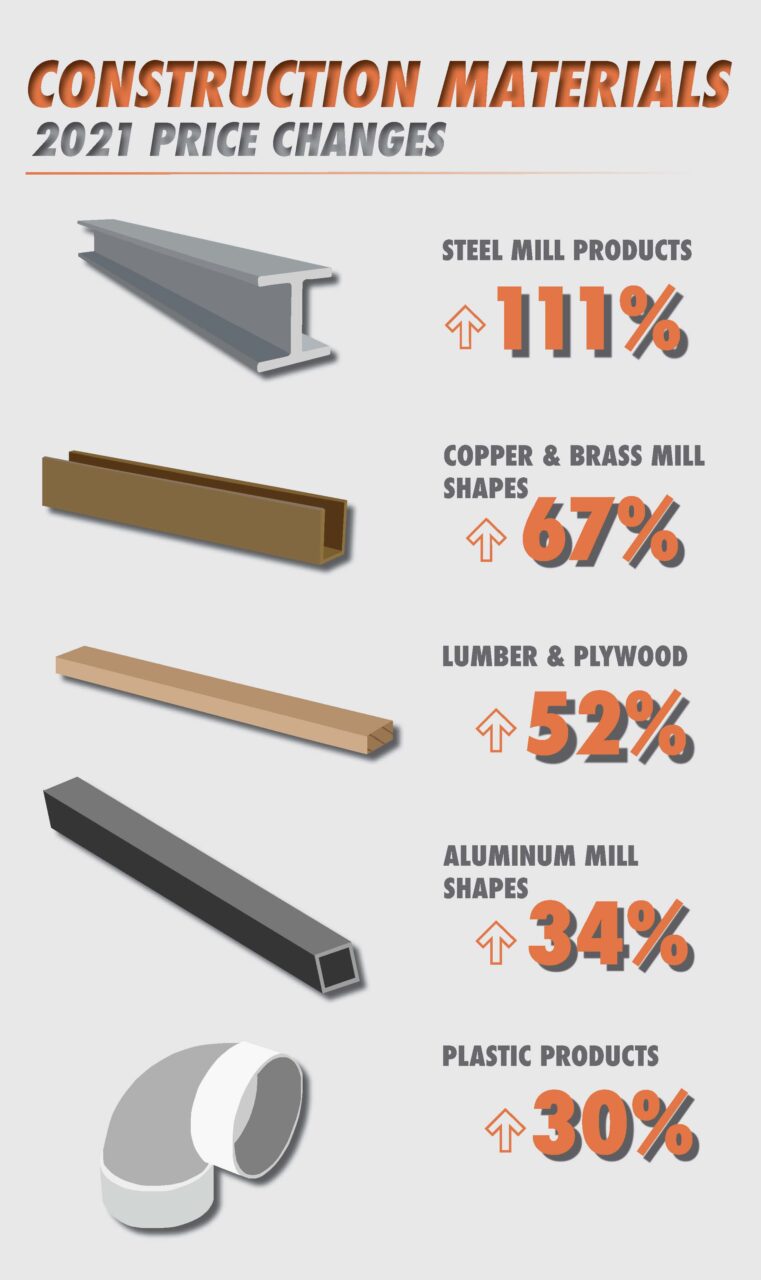

The demand for products is much higher than the inventory of supplies, and that imbalance is raising prices. Building materials such as lumber, steel and plastics have all risen in cost since the pandemic. The price index for steel mill products jumped 111% between April 2020 and August 2021, according to the Bureau of Labor Statistics.

If a single critical component is produced slowly, it will suspend the entire project. Steel joists, a product that supports roofing, “can take months,” said Ken Simonson, the chief economist at the Associated General Contractors of America. “Roofing materials themselves (take) four to eight months.”

Once materials are produced, the next (and maybe greater) challenge is getting them to the construction site. Companies in the U.S. rely on suppliers from around the world for materials and the shipping process is messy right now.

“Some things aren’t even produced in the U.S. so you have to source those from Asia or Europe or some other location,” Simonson said. “That means you’re at the mercy of a shipping capacity, a port capacity, a rail or trucking capacity.”

“On average, there are 25 ships sitting off the port of Los Angeles waiting to be unloaded,” Webb said. “What happened is that tightly orchestrated system in the shipping side of things, when you have people that couldn’t come to work because of COVID-19 it starts backing up the ships, the rail, all the shipping side of it just got so backed up.”

The number of ships waiting to be docked changes daily, but docks have been congested since September. At times, there have been more than 95 ships waiting off the port of Los Angeles and Long Beach according to Business Insider.

Shipments from Asia, especially China, depend on the West Coast ports to bring goods into the U.S. The ships congesting those ports are filled with shipping containers which need to be emptied and sent back to China and other countries where product is ready to get transported.

Warehouse workers and truck drivers are both essential to the shipping process, and currently in short supply. These shipping complications highlight a need in the U.S. for more highway and port capacity as well as manpower. It could be beneficial for legislature to give more funding to infrastructure, Simonson explained.

“Labor is a constant and we’re really short (on) manpower,” said Steve Caldwell, an executive officer with the Utah Valley Home Builders Association. “There aren’t enough people in the industry to keep up with the demand.”

In March 2018, President Donald Trump set tariffs on imported steel and aluminum from every country except Canada and Mexico. There is a 25% tariff on imported steel and a 10% levy on aluminum. These products are both critical to the home-building process. Tariffs on products such as these and other building materials drive up the cost of building a home, resulting in a tax on the consumer.

“There are some items that are just hard to get past the border because there are so many tariff and quota laws around them,” Webb said. “It slows everything down.”

Some countries, such as Brazil and Argentina, chose quotas in lieu of U.S. tariffs. Quotas set restrictions on the quantity of a material a country can export to the U.S. each year. Usually, quota limits are filled early in the year, forcing U.S. buyers to wait until the beginning of the next year to get the materials they need.

“The problem with tariffs and quotas is they make the process unpredictable,” Webb said. “(Tariffs and quotas) certainly will not get us out of this mess, in fact they probably exasperate the mess.”

Logistically, tariffs and quotas slow down the supply chain process. BYU professors of global supply chain management believe the removal of these tariffs could potentially kickstart the supply chain into normalcy.

“I think the biggest hurt is coming from the 25% tariff put in place by President Trump,” Simonson said. “The easiest, quickest step is that the president can remove those tariffs.”

These challenges created a perfect storm for American contractors. The demand for housing without the supplies or manpower to finish jobs becomes useless. During normal times, the supply chain has predictable behavior. Contractors know how much materials cost and when they need to order them to get them in time. The lack of predictability in the supply chain has become a tremendous challenge for contractors.

When a contractor wins a contract for a home, they quote a firm price or “guaranteed maximum price” before they start the project. Contractors make their best guess on how much the project will cost. The unpredictable spikes in cost for materials have left many builders without enough funding to complete construction on a home.

“Predictable costs are always better, even if they’re rising,” Collins said. “If they’re rising and predictable that’s fine. If they’re unpredictable, either up or down, that’s when it becomes hard to pinpoint what the price should be.”

“It has gotten really expensive,” said Tom Foster, another global supply chain professor at BYU. “It’s not that unusual for a contractor to get halfway through a project and then come back and say, ‘this is going to cost you double what we originally contracted for.’”

There are multiple supply chain prongs that feed into the construction of a home. Floors, lights, appliances, sheet rock, concrete and wood all saw disruptions that forced contractors to extend their loans. This makes it harder to build homes on time and on budget.

“It’s been really taxing and trying because (contractors) can’t meet their promises or they can’t do it for the price they would like,” Caldwell said. “It’s made it really difficult.”

Professors of global supply chain at BYU believe the supply chain won’t right itself out until 2023. Removing stress from the supply chain depends heavily on the COVID-19 pandemic. Even if the chain is operating well, spikes in the pandemic result in factory closures and workers staying at home which causes more bottlenecking.

Americans still want new homes, but there is a systemic shortage of lots and materials needed to build homes in the U.S. The constrained supply of housing and materials has risen the cost of building a home. Once the costs reach a certain price point, buyers will be unwilling to pay and the buying frenzy will likely slow down so the supply chain can find balance once again, Collins explained.