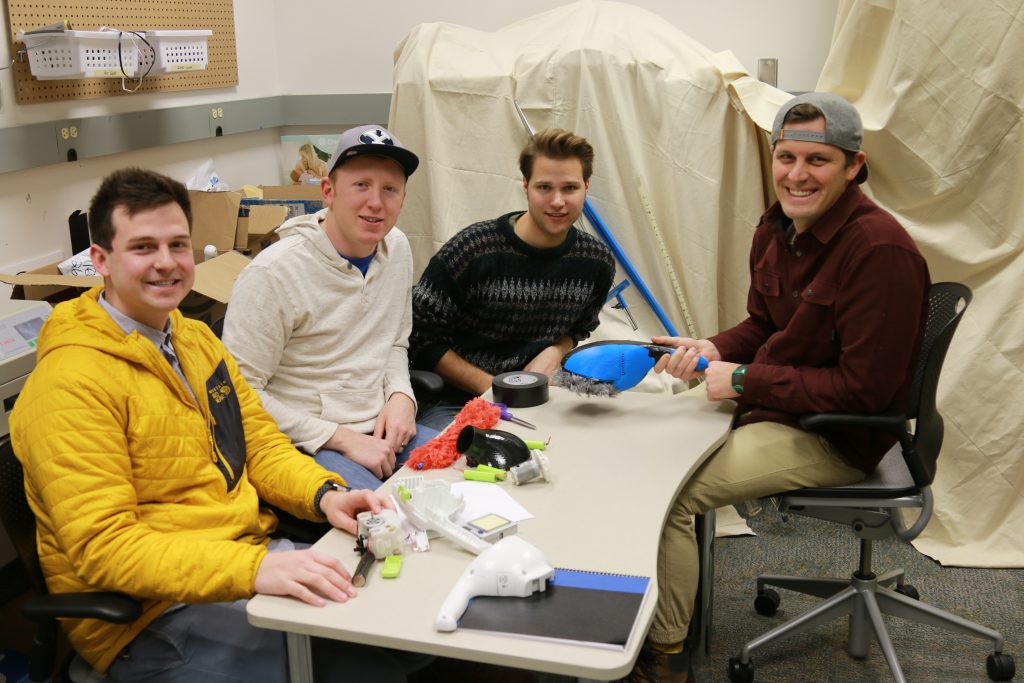

A team of mechanical engineering students are working with an entrepreneur to develop a handheld vacuum they hope will change the way people clean their houses for their capstone project.

Entrepreneur and BYU engineering alumnus Ron Hilton said he came to the student team with the idea of a “VacDuster,” a handheld vacuum used for dusting. He said he noticed dust would resettle when he was cleaning, so he came up with a circular rotating bristle system to suck the dust in and trap it.

Member of the capstone team Jacob Olson said they meet with Hilton every week to give Hilton updates and to show him their progress. Hilton said he has been extremely pleased with the team’s ability to hear and apply his comments and criticism.

“They are both creative in their thinking and carefully methodical in their approach. They listen to my feedback, and then build upon that to develop new ideas of their own,” Hilton said. “My greatest satisfaction is to see their enthusiasm for learning and applying the principles that they have learned at BYU in such a professional manner.”

Olson said learning to apply Hilton’s feedback effectively has been one of the greatest lessons he’s learned through the project process.

“One thing that is important is that you do stick with their requirements because that’s what ends up being the most important,” Olson said. “When you try to diverge from what the sponsor wants, you end up wasting time.”

What makes this project an even greater experience is VacDuster has already been registered as a Utah corporation, so this product will actually be viable to take all the way to the market, according to Hilton.

“Having been an engineering student myself at BYU, I knew how valuable it is to have industry mentorship,” Hilton said. “Having also acquired business experience as an entrepreneur, I am also hoping to get students involved in the business side of the project.”

The VacDuster team is one of 32 capstone projects BYU mechanical engineering students began working on in September in accordance with sponsoring companies, entrepreneurs and humanitarian organizations.

Kelly Marcum, Department of Mechanical Engineering external relations coordinator, said pairing students with these outside entities gives students the opportunity to apply what they’ve learned theoretically in classes to real-life clients and situations.

“The main purpose of capstone is to teach students how to be presented a problem, conceptualize an idea to fix the problem, design, build and test a solution for that problem,” Marcum said.

Marcum said the mechanical engineering capstone projects are very time consuming, as students work two hours a day, five days a week, for two semesters. He said most students consider these intensive, difficult projects the most defining class of their whole BYU experience.

The VacDuster team coach and mechanical engineering adjunct professor Dorothy Taylor said the development process has helped the students see what they can really achieve after graduation.

“I love seeing students get excited about using their engineering education on real world problems, knowing that they can make a difference in the world … Students learn to be resourceful, and ultimately become the experts of their particular project,” Taylor said. “Students who are committed and who fully participate gain skills that will benefit them not only in their future careers, but in all areas of their life.”